BORNEWA TRANSFORMATION

BORNEWA FIBER

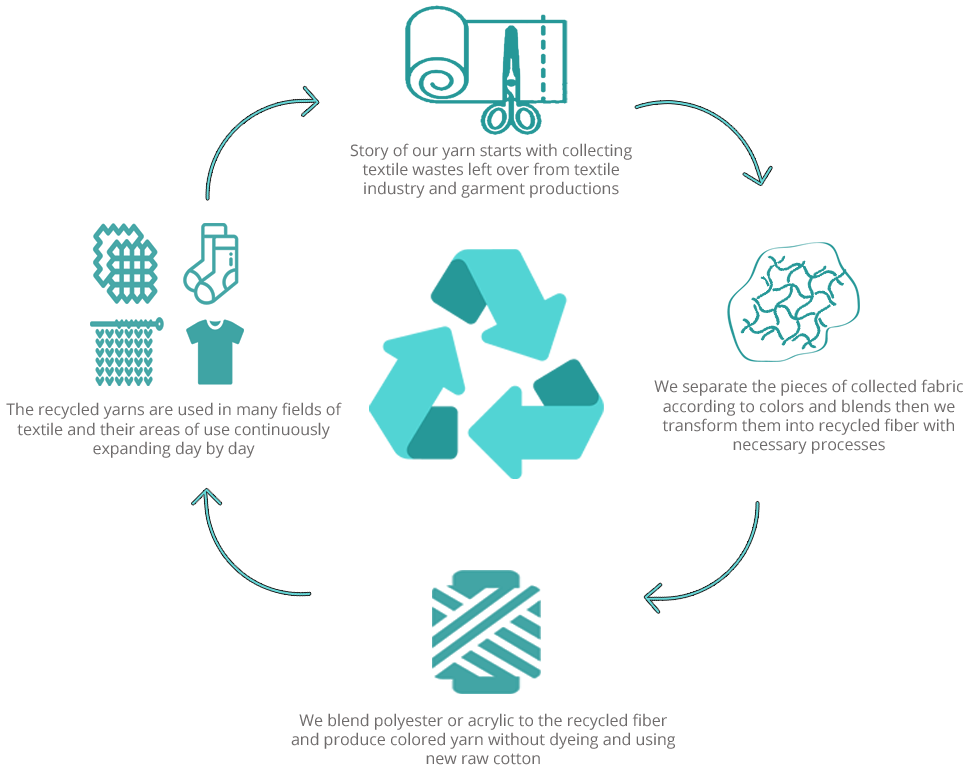

First, the unusable scraps of fabric are collected from textile and ready garment establishments for the production of BORNEWA Fibers. The collected scraps are separated according to their content, color and types. Uniting our twenty five years of experience in the yarn industry with our state-of-the-art technology lines, high quality fiber is produced. The produced BORNEWA fiber is put at the disposal of all industries that engage in the production of yarns, fabric and spun lace, and especially BORNEWA yarn production with high quality and wide range of color alternatives.

Factory Tour

Factory Tour

BORNEWA YARN

Combining our facility which is equipped entirely with state-of-the-art technology machinery and our twenty five years of yarn production experience the BORNEWA yarn is produced using high quality colored fibers which are produced at our integrated fiber facility in a wide range of color alternatives that suit the demands of end users.

PRODUCTS

Having stepped into the textile industry in 1993 with its open-end yarn facility, continued with ring and knitting facility in 2003 then ELSE was established its yarn dyeing facilities in 2007 and become an integrated facility with a forty two thousand meter indoor area. It has contributed in the country’s economy with the export to many countries of the world, especially in Europe.

Textile products are materials that are needed in many areas, starting with the most basic needs of our lives and their production increasingly continues. Recycling is seen as the best solution for both natural and synthetic based textile wastes in order to reduce the environmental effects of production processes and to prevent the problems that can occur when they are dumped in the nature. Recycling of the scraps that emerge during textile production fulfill an important function in the world.

As ELSE, we have established our regenerated fiber and yarn production facility in 2018 with the purpose of keeping pace with this development in the world and putting our experience in the textile industry. All colors and blends are mentioned in color chart. Different counts and blends can be produced on request.

Textile products are materials that are needed in many areas, starting with the most basic needs of our lives and their production increasingly continues. Recycling is seen as the best solution for both natural and synthetic based textile wastes in order to reduce the environmental effects of production processes and to prevent the problems that can occur when they are dumped in the nature. Recycling of the scraps that emerge during textile production fulfill an important function in the world.

As ELSE, we have established our regenerated fiber and yarn production facility in 2018 with the purpose of keeping pace with this development in the world and putting our experience in the textile industry. All colors and blends are mentioned in color chart. Different counts and blends can be produced on request.

PRODUCTS & END USES

| Yarn Count | Blends | Weaving | Tricot | Knitting | Sock |

| Ne 4/1 | %50 Recycled Cotton / %50 PES or Acrylic → %98 Recycled Cotton / %2 PES or Acrylic |

|

|||

| Ne 8/1 | %50 Recycled Cotton / %50 PES or Acrylic → %95 Recycled Cotton / %5 PES or Acrylic |

|

|||

| Ne 12/1 | %50 Recycled Cotton / %50 PES or Acrylic → %90 Recycled Cotton / %10 PES or Acrylic |

|

|

|

|

| Ne 16/1 | %50 Recycled Cotton / %50 PES or Acrylic → %80 Recycled Cotton / %20 PES or Acrylic |

|

|

|

|

| Ne 18/1 | %50 Recycled Cotton / %50 PES or Acrylic → %80 Recycled Cotton / %20 PES or Acrylic |

|

|

|

|

| Ne 20/1 | %50 Recycled Cotton / %50 PES or Acrylic → %80 Recycled Cotton / %20 PES or Acrylic |

|

|

|

|

| Ne 20/2 | %50 Recycled Cotton / %50 PES or Acrylic → %80 Recycled Cotton / %20 PES or Acrylic |

|

|||

| Ne 24/1 | %50 Recycled Cotton / %50 PES or Acrylic → %70 Recycled Cotton / %30 PES or Acrylic |

|

|

|

|

| Ne 28/1 | %50 Recycled Cotton / %50 PES or Acrylic → %60 Recycled Cotton / %40 PES or Acrylic |

|

|

|

|

| Ne 30/1 | %50 Recycled Cotton / %50 PES or Acrylic → %60 Recycled Cotton / %40 PES or Acrylic |

|

|

|

|

| Ne 30/2 | %50 Recycled Cotton / %50 PES or Acrylic → %60 Recycled Cotton / %40 PES or Acrylic |

|

|

||

| Ne 30/3 | %50 Recycled Cotton / %50 PES or Acrylic → %60 Recycled Cotton / %40 PES or Acrylic |

|

|||

| Different counts and blends can be produced on request. | |||||

STANDARDS

BRANDS

QUALITY POLICY

The BORNEWA yarn quality is audited with the OEKOTEX STANDARD 100 certificate throughout the production line. Our USTERIZED laboratory is equipped with all devices and hardware that will measure the compliance of the final product with international standards. The COROLAB XQ technology used in thread production also guarantees to serve the customer quality at the end point.

Our quality policy is to carry out and develop reliable production that exceeds the expectations of customers in line with the vision of ELSE and using the developing technologies. It is to raise, in line with the continuous improvement approach, the efficiency of all our processes to a level that can compete in the international level, to encourage innovative and creative approaches, and to carry out trainings that will improve technical and behavioral competences. We work with all we have to set an example as an establishment integrated with the Environment, Occupational Health and Safety Management Systems.

Our quality policy is to carry out and develop reliable production that exceeds the expectations of customers in line with the vision of ELSE and using the developing technologies. It is to raise, in line with the continuous improvement approach, the efficiency of all our processes to a level that can compete in the international level, to encourage innovative and creative approaches, and to carry out trainings that will improve technical and behavioral competences. We work with all we have to set an example as an establishment integrated with the Environment, Occupational Health and Safety Management Systems.

ENVIRONMENTAL BENEFITS

Although synthetics are perceived as the raw material group that causes the most problems in terms of environment, natural fibers also cause various problems. The environmental damage (other, helpful organisms dying, causing fish deaths, leaking into underground waters, etc.) caused by pesticides used in the production of cotton, which is another fiber that is produced and used the most along with polyester gets reaction from environmentalists also due to reasons such as the environmental effects caused by genetically modified cotton production and chemical based fertilizer use.

The environmental damage caused by its production process harms the “green” image of the cotton fiber despite the fact that it decomposes in a significantly shorter period of time in comparison to synthetics. Synthetic fibers, on the other hand, is the group among solid textile wastes that cause the most serious problems in the environment, due to the long time it takes to decompose, along with the environmental and economic problems related to it being obtained from petroleum based products.

Regenerated (recycled) fiber and yarn production which has been accepted as eco-friendly, helps reduce the use of garbage incineration and storage areas by recycling textile wastes. Thanks to the processes that do not require dyeing, it reduces water use and pollution. For example, 11 thousand liters are needed to obtain 1 kg of cotton and 130 liters are needed to dye 1 kg of yarn. Daily 237 million liters of water is saved with recycling processes

The environmental damage caused by its production process harms the “green” image of the cotton fiber despite the fact that it decomposes in a significantly shorter period of time in comparison to synthetics. Synthetic fibers, on the other hand, is the group among solid textile wastes that cause the most serious problems in the environment, due to the long time it takes to decompose, along with the environmental and economic problems related to it being obtained from petroleum based products.

Regenerated (recycled) fiber and yarn production which has been accepted as eco-friendly, helps reduce the use of garbage incineration and storage areas by recycling textile wastes. Thanks to the processes that do not require dyeing, it reduces water use and pollution. For example, 11 thousand liters are needed to obtain 1 kg of cotton and 130 liters are needed to dye 1 kg of yarn. Daily 237 million liters of water is saved with recycling processes

NEWS

We export most of the recycled yarns which is produced with Bornewa brand to many countries of the world. We aim to contribute to the economy of our country by increasing our exports and we participate in fairs abroad and in the country. You can follow all about fairs and development in the company from here.

110841102555.jpg)

13754391292579.jpg)

12678641185005.jpg)

15757561492897.png)

16457181562858.jpg)